Semi Automatic Coiler 6.jpg

In today’s dynamic landscape of pipe manufacturing, coilers are quickly becoming more of a necessity than a luxury.. These specialized machines, used for coiling PE pipes, HDPE pipes, or even Drip Irrigation pipes, are indispensable across industries such as utility infrastructure, irrigation, construction, and all types of conduit. With today’s rising manufacturing costs and customers looking for the lowest prices on the finished product, a coiling machine is becoming a must-have for any pipe manufacturing facility. They not only serve a functional purpose but also contribute significantly to enhancing efficiency, precision, and overall product quality.

Coilers refer to machines designed specifically for coiling flexible materials like PE pipe, HDPE pipe, conduit, drip irrigation, or any other types of flexible plastic pipes, into compact coils. This coiling process is essential for the storage, transportation, and further processing of these materials. These machines come in different sizes and configurations based on the material being handled and the specific requirements of the production process.

Diverse Varieties of Coilers

There exist various types of coiler machines customized for specific applications. For instance;

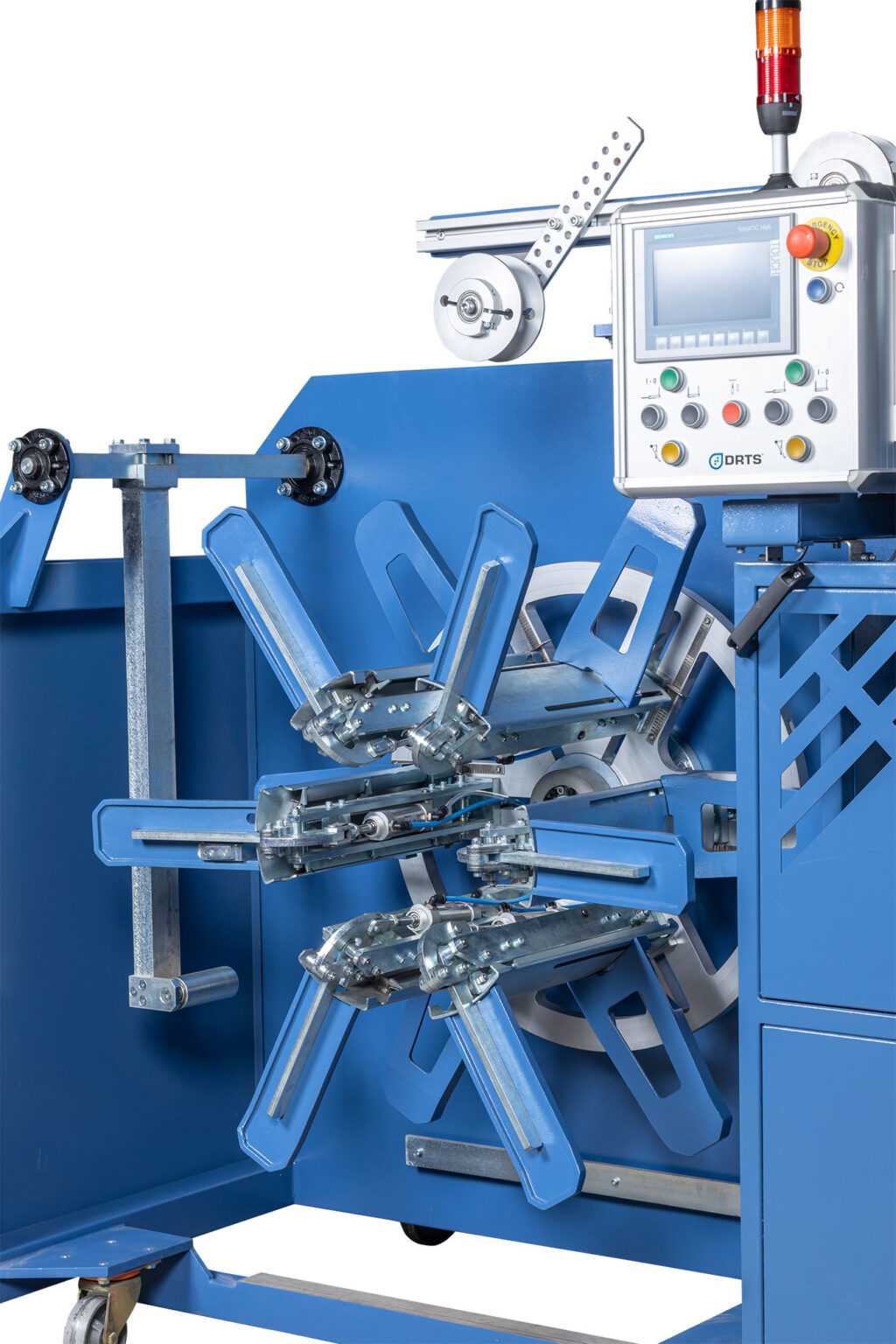

Drip Irrigation Coilers can handle either round or flat irrigation pipes and can be configured to coil at various diameters. There are also both semi-automatic and fully automatic coilers that can coil different types of PE pipe into virtually any inner or outer diameter as needed for the application. These machines ensure uniform and secure winding to prevent tangling or damage during storage or transportation all while reducing manpower and increasing production speed and efficiency.

Coilers play a pivotal role in industries such as Drip Irrigation, Gas, Water, and construction by efficiently coiling pipes or conduits for convenient storage and transit. They are indispensable in large-scale production environments where space utilization and operational efficiency are critical considerations.

In the realm of plastic manufacturing, coilers are commonly used to wrap extruded plastic products like tubing or piping into coils, making it easier to handle and ship them.

The Importance of Coilers in Manufacturing

Coilers play a crucial role in modern manufacturing for various reasons;

1. Enhanced Efficiency; Coilers automate the winding of materials, reducing the need for manual labor and speeding up production. This automation ensures consistency and quality by minimizing human errors.

2. Space Optimization; By coiling long materials, manufacturers can maximize storage space usage, especially beneficial for industries dealing with large quantities of materials.

3. Transportation Advantages; Coiled materials are more manageable and secure during transportation thanks to coilers, preventing damage and waste while ensuring intact delivery. Modern coil winding machines come with advanced controls for precise winding that meet industry standards.

4. Customization; These coil winding machines can be programmed to create coils in different inner and outer dimensions based on production requirements. This flexibility is vital in manufacturing environments where tailored solutions are increasingly important.

The role of coil winding machines in manufacturing is set to expand as manufacturers are looking for ways to reduce cost and manpower. Integrating smart technologies such as IoT and AI is transforming these machines into highly advanced tools capable of monitoring and adjusting in real-time. This progress will lead to increased efficiency, accuracy, and customization in the production process.

In essence, coil winding machines play a crucial part in modern manufacturing, enhancing efficiency, precision, and overall product quality across various industries. As technology continues to evolve, these machines will play an even larger role, cementing their importance in the manufacturing sector.

Source link

2024-08-28 05:32:25

Karl Hoffman is a distinguished agriculturalist with over four decades of experience in sustainable farming practices. He holds a Ph.D. in Agronomy from Cornell University and has made significant contributions as a professor at Iowa State University. Hoffman’s groundbreaking research on integrated pest management and soil health has revolutionized modern agriculture. As a respected farm journalist, his column “Field Notes with Karl Hoffman” and his blog “The Modern Farmer” provide insightful, practical advice to a global audience. Hoffman’s work with the USDA and the United Nations FAO has enhanced food security worldwide. His awards include the USDA’s Distinguished Service Award and the World Food Prize, reflecting his profound impact on agriculture and sustainability.

Asmongold vs. Elon Musk — Tesla’s self-driving mode gives you back the most important thing during rush hour—your game time.