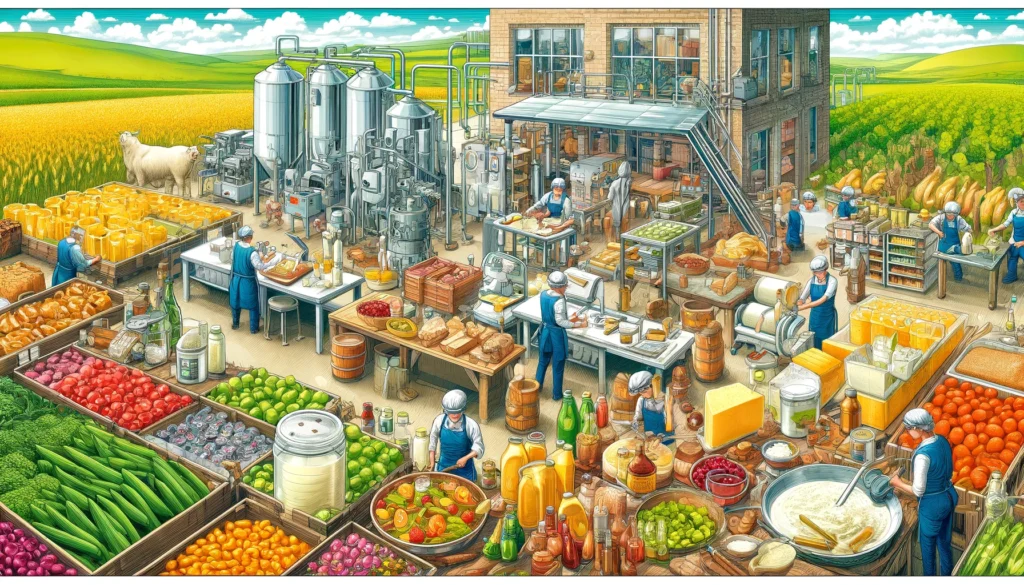

Food Processing A detailed and vibrant illustration depicting food processing on a farm. The scene shows farmers and workers processing various agricultural products 2.webp.webp

Definition: Food Processing

Overview

Food processing refers to the methods and techniques used to transform raw ingredients into finished food products that are safe, nutritious, and appealing to consumers. This includes activities such as cleaning, cutting, cooking, canning, freezing, drying, and packaging. Food processing extends the shelf life of food, enhances its flavor and texture, and ensures it meets safety standards. It plays a crucial role in the food supply chain, enabling farmers and producers to add value to their products and meet consumer demand.

Benefits of Food Processing

Extended Shelf Life

One of the primary benefits of food processing is the extension of shelf life. Processes such as canning, freezing, and drying help preserve food by inhibiting the growth of microorganisms and slowing down spoilage. This allows food to be stored for longer periods, reducing waste and ensuring a stable food supply.

Fall off the barn roof and busted your keister? Life on the farm or ranch can be tough on the bum. Need a break? Laugh it off at FarmerCowboy.com, the #1 farm humor site. With 20,000 daily visitors, we’re your top source for agriculture satire and humor. Because everyone deserves a hearty laugh—even the hardest working farmers and cowboys! Join us and turn those long days into fun tales at FarmerCowboy.com.

Enhanced Food Safety

Food processing helps ensure the safety of food by eliminating or reducing harmful pathogens. Techniques such as pasteurization, sterilization, and irradiation kill bacteria and other contaminants, making food safer for consumption. Compliance with food safety regulations and standards is a key aspect of food processing.

Improved Nutritional Value

Processing can enhance the nutritional value of food by fortifying it with vitamins and minerals. For example, fortifying flour with iron and folic acid or adding vitamin D to milk improves the nutritional profile of these foods. Additionally, processing methods like freezing and drying help retain the nutritional content of fruits and vegetables.

Components of Food Processing

Cleaning and Preparation

The first step in food processing is cleaning and preparing raw ingredients. This involves removing dirt, debris, and any unwanted parts from the raw materials. Washing, peeling, and cutting are common preparation techniques that ensure the ingredients are ready for further processing.

Processing Techniques

Various techniques are used to process food, depending on the desired end product. Common methods include:

- Canning: Sealing food in airtight containers and heating to kill bacteria.

- Freezing: Rapidly lowering the temperature to preserve food and prevent spoilage.

- Drying: Removing moisture to inhibit microbial growth and extend shelf life.

- Cooking: Applying heat to improve taste, texture, and safety.

- Fermentation: Using microorganisms to convert sugars into alcohol or acids, enhancing flavor and preservation.

Packaging

Packaging is a critical component of food processing, protecting food from contamination and damage during storage and transport. Packaging materials and methods vary depending on the type of food and its intended use. Common materials include glass, metal, plastic, and paper, each offering different levels of protection and convenience.

Techniques for Effective Food Processing

Quality Control

Quality control is essential in food processing to ensure that products meet safety and quality standards. This involves regular monitoring and testing at various stages of processing to detect and address any issues. Quality control measures help maintain consistency, safety, and consumer satisfaction.

Innovation and Technology

Advancements in technology play a significant role in improving food processing methods. Innovations such as high-pressure processing, pulsed electric fields, and advanced packaging materials enhance the efficiency, safety, and quality of processed foods. Staying updated with the latest technologies can give producers a competitive edge.

Sustainable Practices

Sustainable food processing practices focus on reducing waste, conserving energy, and minimizing the environmental impact. Techniques such as using by-products for animal feed, recycling water, and adopting energy-efficient equipment contribute to sustainability. Emphasizing eco-friendly practices can also attract environmentally conscious consumers.

Economic Considerations

Investment in Equipment

Food processing requires significant investment in equipment and infrastructure. Costs include machinery for cleaning, processing, and packaging, as well as facilities for storage and distribution. While the initial investment can be high, the long-term benefits of increased production capacity and product quality often justify the expense.

Return on Investment

Conducting a cost-benefit analysis helps producers assess the return on investment for food processing activities. This analysis should consider factors such as increased shelf life, enhanced food safety, higher product value, and expanded market reach. Efficient processing methods can lead to greater profitability and sustainability.

Environmental Impact

Waste Management

Proper waste management is crucial in food processing to minimize environmental impact. This includes recycling and repurposing by-products, reducing food waste, and managing water and energy use efficiently. Sustainable waste management practices contribute to the overall sustainability of the food processing industry.

Energy and Resource Use

Food processing can be resource-intensive, requiring significant amounts of water and energy. Implementing energy-efficient technologies and practices helps reduce the environmental footprint. Renewable energy sources, such as solar or wind power, can also be integrated to enhance sustainability.

Case Studies

Case Study 1: Freezing Technology in Vegetable Processing

A vegetable processing plant in Oregon implemented advanced freezing technology to preserve the nutritional content and quality of their produce. By adopting individual quick freezing (IQF) methods, the plant reduced waste, extended shelf life, and improved the overall quality of their products, resulting in increased market share and customer satisfaction.

Case Study 2: Sustainable Canning Practices

A fruit canning company in California adopted sustainable practices by recycling water used in the cleaning process and utilizing solar energy for canning operations. These initiatives reduced the company’s environmental impact, lowered operational costs, and attracted environmentally conscious consumers, boosting the company’s reputation and sales.

Conclusion

Food processing is a vital component of the food supply chain that enhances the safety, quality, and value of agricultural products. By implementing effective processing techniques, maintaining quality control, and adopting sustainable practices, producers can meet consumer demand and ensure the long-term success of their operations. Understanding the components and benefits of food processing allows farmers and producers to make informed decisions and capitalize on the opportunities it offers. As technology and consumer preferences continue to evolve, staying innovative and adaptable in food processing practices will remain crucial for competitiveness and sustainability.

Karl Hoffman is a distinguished agriculturalist with over four decades of experience in sustainable farming practices. He holds a Ph.D. in Agronomy from Cornell University and has made significant contributions as a professor at Iowa State University. Hoffman’s groundbreaking research on integrated pest management and soil health has revolutionized modern agriculture. As a respected farm journalist, his column “Field Notes with Karl Hoffman” and his blog “The Modern Farmer” provide insightful, practical advice to a global audience. Hoffman’s work with the USDA and the United Nations FAO has enhanced food security worldwide. His awards include the USDA’s Distinguished Service Award and the World Food Prize, reflecting his profound impact on agriculture and sustainability.