image 8 1.png

With our 35+ years in the industry, DRTS is continuously innovating solutions to improve our machines and products. One of our greatest partners in this ongoing endeavor are our loyal clients who provide a steady feed of ideas for improvements. One such collaboration has created the DRTS Hybrid PE Pipe Haul-Off/Puller.

When building a production line, the rule of thumb is, build the equipment to fit the largest product diameter. Meaning, for example, if the PE pipe production line is for pipes from 20-110mm, we optimize the production line to accommodate the largest size pipe (in this case 110mm).

This means we build the die-head, vacuum tank, cooling tanks, haul-off/puller, cutter, pipe coiler all to handle the largest diameter.

In such cases, this usually means the smaller pipe diameters which naturally should be run at a faster production speed due to its smaller size, is limited in production speed due to equipment being optimized for the larger diameter of the production line range.

Such an example is the pipe haul-off/puller. A puller that needs to pull a larger pipe diameter (example: 110mm) will be built for torque rather than speed and therefore the same puller cannot do the same efficient job for a 20mm pipe.

Our clients, always want high efficiency machinery. Efficient in electricity, footprint and of course output.

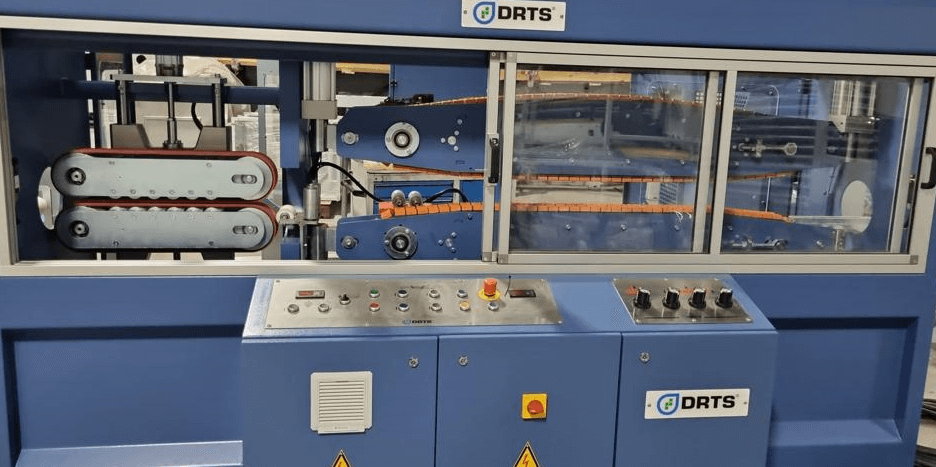

To tackle this “problem” DRTS developed the Hybrid Haul-off/puller. This is a 2-in-1 puller system that employs a dual belt system in a single frame through a single HMI control panel.

For the smaller pipes (16-32mm) a dual lintex belt puller is used. This system has the ability to run at speeds of up to 100 meter per minute. Thus, allowing the production of the smaller pipe diameters to be at higher speeds, making it an efficient production. Whereas in a standard haul-off/puller of up to 110mm the max pulling speeds would normally be around 30 meter per minute.For the larger diameters (40-110mm) a triple arm caterpillar is used. This is the conventional puller system on such PE production lines. This system has the necessary grip torque for these larger diameters.

The DRTS Hybrid Haul-off/Puller not only allows faster and more efficient production speeds, It also saves changeover time between products. Normally a caterpillar belt system from 20-110mm would require a changeover of belt pads when running the smaller sizes. This is so that the gap between the 3 belts will be small enough to grip the small diameter pipes. With the DRTS Hybrid system, this is not required. By a simple press of a button, you choose which belt system to use.

Further, as this unit is in a single frame, it saves footprint and cost. Many companies until now, tried to bypass the problem described above by simply purchasing two haul-offs/pullers that would be interchanged between them depending on what diameter of pipe is being produced. With the DRTS Hybrid Haul-off/puller you save money as you don’t need to buy two units, and save floor footprint as our compact design keeps all in a single frame. All while having the flexibility to tackle the changing needs of the local market.

The DRTS Hybrid Haul-off/puller is a new option available on our turnkey large diameter range PE lines and it can also be integrated into an existing production line as a standalone unit, this can be an easy and relatively cheap upgrade to your existing production lines.

To learn more about this unit or any other PE pipe production equipment, please contact us.

Source link

2023-07-21 02:36:40

Originally posted 2024-06-27 09:08:02.

Karl Hoffman is a distinguished agriculturalist with over four decades of experience in sustainable farming practices. He holds a Ph.D. in Agronomy from Cornell University and has made significant contributions as a professor at Iowa State University. Hoffman’s groundbreaking research on integrated pest management and soil health has revolutionized modern agriculture. As a respected farm journalist, his column “Field Notes with Karl Hoffman” and his blog “The Modern Farmer” provide insightful, practical advice to a global audience. Hoffman’s work with the USDA and the United Nations FAO has enhanced food security worldwide. His awards include the USDA’s Distinguished Service Award and the World Food Prize, reflecting his profound impact on agriculture and sustainability.